Quality is Pride of Workmanship.

INMET is a quality focused organization. We are constantly evolving to improve our processes and controls and to provide the highest quality and service in the industry aiming ZERO defect as a strategy. We have very strong quality principles. They are strategic planning and leadership, a strong customer focus, fact-based management, continuous improvement and total employee involvement.

Our Practice Methodologies

Operational Excellence is our Strength

The operational excellence of INMET is supported by practicing QM Pillar. We have a proactive approach to achieve Zero Defect at manufacturing stage and strive to achieve highest customer satisfaction. Quick response to the concerns and implementation of prevention Poka-Yoke for defects, are our strengths.

World Class Expertise to Deliver the Best in Class

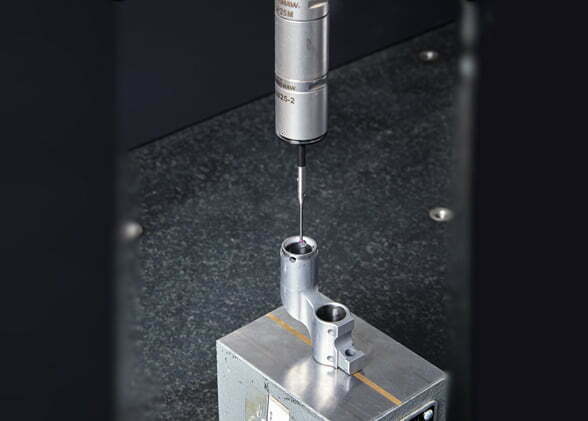

RM Inspection is carried out on RM to ensure that the quality standards, with support of fully-equipped metallurgical and meteorological labs. INMET has state-of-the-art inspection facility with advanced inspection equipment to ensure and guarantee superior quality standards. Advanced SCADA control ensures the process parameters are maintained.

Customer complaints are handled pro-actively and positively, with the support of ICA and PCA with long term standardization to avoid repeat issues. QA Lab with Quality Checking ability and Instruments inspect the part to ensure its quality and measurement as per the drawing.