Overview

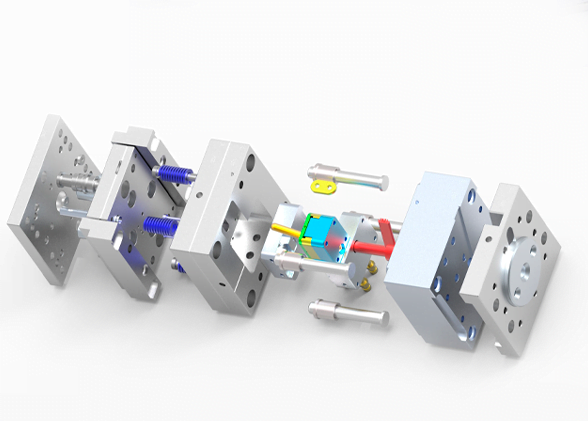

INMET has a well-equipped tooling capacity with manufacturing expertise in precision injection molds, fixtures and Gauges. Our main objective is to provide best services with fine durability interlinked with low cost automation and lean manufacturing with minimized lead time. To achieve this, we invest in advanced machines and latest technology.

- Highly efficient, accurate and productive CNC Vertical Milling Machine for hard part and electrodes milling

- CNC Electrode Discharge Machine (EDM) for creating complex shapes from extremely hard materials with spark erosion

- CNC Wire EDM Machine to accurately cut the most intricate parts and delicate shapes including small or odd angles, sharp corners, counters,

- cavities and external or internal tapers Surface Grinding Machine to produce a smooth finish on flat surface

- Quick Setting Grinding Fixture

- Probing System in Milling

- Tool Setter in Milling

- Mold Validation System at Validation Stage