Design Considerations for Metal Injection Molding

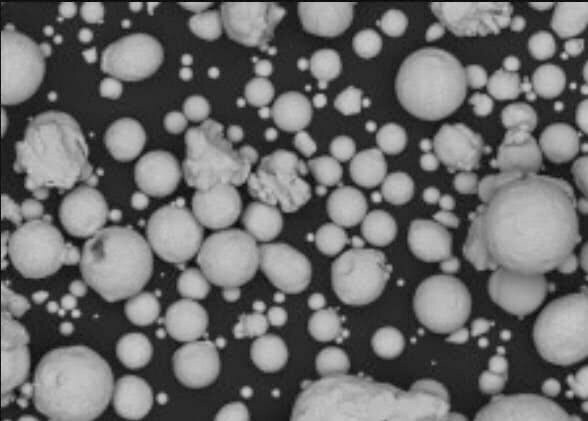

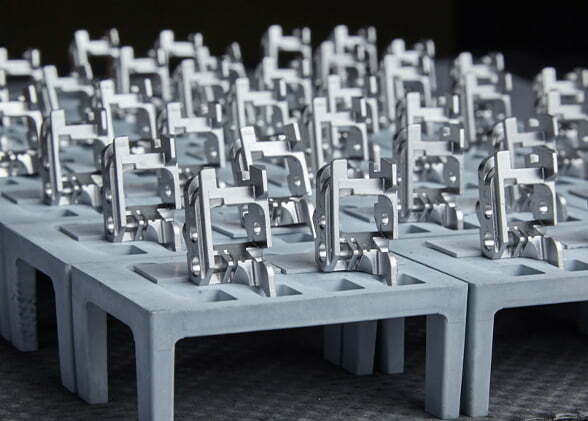

Metal Injection Molding (MIM) is an advanced technology, which produces relatively small (0.03 grams to 150 grams), complex, net, or near-net parts in large volumes. MIM design is principally similar to plastic injection molding. There are various key design considerations for MIM.

Design Guidelines

Design Guidelines

Following are the main properties of the products which are appropriate for MIM technology.

Following are the main properties of the products which are appropriate for MIM technology.

Design Flexibility

MIM process is highly beneficial for product designers, since it offers freedom and flexibility in design to generate complex profile parts. The integration of the parts and tools gives amazing results in finer features. Miniature parts with difficult geometry can be produced in single operation.

Weight and Size

MIM is ideal for parts weighing less than 100 grams. The most cost-efficient applications are less than 50 grams. The parts which weight of up to 250 grams can also be processed depends upon the geometry. MIM helps in reducing weight and works excellently for small and micro-sized parts with weights of less than 0.1 gram.

Surface Finish

MIM parts are known for good quality surface finish on as formed parts. Surface finish can be achieved around 0.6 Ra on as sintered parts. Various detailing features such as knurling, etc. can be developed on products with MIM. Fine surface finish can be achieved without any additional polishing or grinding procedures.

Production Volumes

MIM process is scalable and mass production of complex parts reduces the cost. The material wastage is minimal. The parts which have been produced in earlier cycles can be reused. Thus, MIM is not only optimum cost saving, but eco-friendly as well, which reinforces MIM as a green technology.