Rapid Prototyping

Prototyping is a process of engineering product design concept. A prototype is a preliminary version of the end-product used to evaluate the design, test the technology, analyse the working principle, and provide final product specifications. Prototypes are an integral part of engineering product design and, more importantly, of new product development.

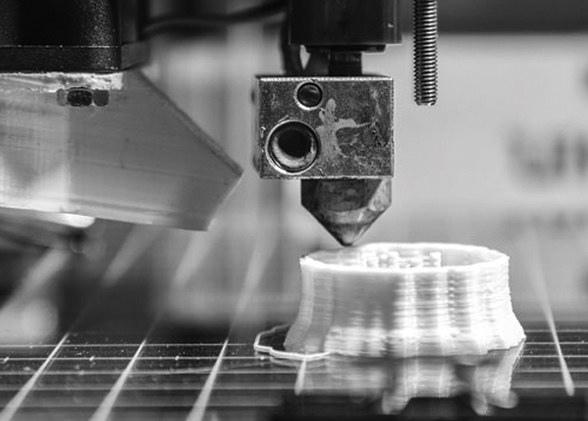

INMET has capability to support customer in early validations with its rapid prototyping abilities through MIM & In-house 3D Printing facility.

Rapid Prototyping Work flow

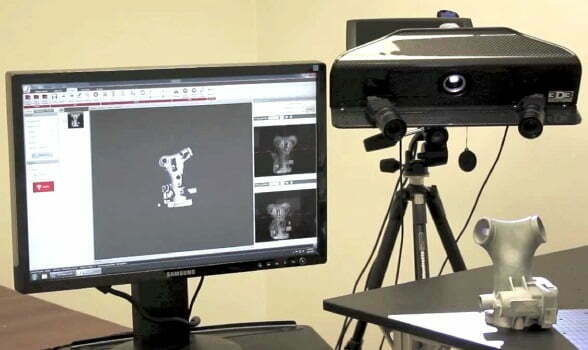

Reverse Engineering is a thorough process, which involves capturing 3D dimensional data of a physical object, processing 2D/ 3D data, CAD creation, design modification, inspection and 3D printing.

Selection of prototyping method based on the nature of requirement for prototype development and its lead time of sample development.

| Proto Method | Development Time |

|---|---|

| Metal 3D printing | 10 Days |

| MIM Single Cavity Insert method | 25 Days |

| MIM Baby Molds with Different Components | 40 Days |

| MIM Standard Multi Cavity Mold – Production Tool | 60 Days |